Market Context

Current electromechanical test instruments are often limited by insufficient repeatability and inadequate traceability. The ESPY series is designed to close this gap, providing SI-traceable measurements with defined uncertainty budgets, focused on reproducible characterization of piezoelectric materials. Feedback from industrial and scientific users directly informed the instrument architecture.

Key Measurement Capabilities

Direct measurement of piezoelectric charge coefficients (d-coefficients) in compliant materials poses two main challenges:

- Low piezoelectric coupling produces displacement charges close to background noise.

- Low elastic modulus requires precise force application without introducing parasitic signals.

ESPY instruments address both conditions:

- Static and dynamic forces adjustable with 100 µN precision.

- Low-noise front-end electronics using virtual ground amplification.

- Current measurement with 100 fA resolution.

- Charge detection with sub-pC accuracy.

Environmental and Functional Extensions

- Compatible with environmental chambers for measurements under controlled temperature conditions.

- Enables simultaneous monitoring of dielectric permittivity, dielectric loss, and leakage current before, during, and after mechanical excitation.

- Supports studies of electromechanical coupling, electrode degradation processes, and long-term stability (mechanical/electrical aging).

Suitable Materials Range

ESPY instruments are compatible with a wide range of ferroelectric and piezoelectric materials:

- Inorganic piezoelectric crystals: Quartz (SiO₂), Tourmaline, Rochelle Salt (sodium potassium tartrate).

- Single-crystal oxides: Lithium Niobate (LiNbO₃), Potassium Niobate (KNbO₃).

- Polycrystalline piezoelectric ceramics: Lead Zirconate Titanate (PZT), Barium Titanate (BaTiO₃), Lead Magnesium Niobate (PMN).

The instruments are particularly suited for compliant materials and piezoelectric composites, including:

- Synthetic piezoelectric polymers: poly(vinylidene fluoride) (PVDF), PVDF-TrFE, poly-L-lactic acid (PLLA), polyhydroxybutyrate (PHB), poly-γ-benzyl-L-glutamate (PBLG), nylons (e.g., Nylon-11, Nylon-7, Nylon-12).

- Natural polymers and biopolymers: collagen, keratin, chitin/chitosan, cellulose, silk fibroin, DNA.

- Mineralized tissues and biological composites: bone, dentin, enamel, collagen-rich tissues such as tendons, ligaments, and cartilage.

- Amyloid fibrils and plant-derived biomaterials: wood, cotton, starch-based biopolymers.

- Microbial and engineered biomaterials: bacterial cellulose, genetically engineered peptides and proteins, designed β-sheet motifs, virus-based materials such as M13 bacteriophage.

Integration with aixPES Modular System

The ESPY series integrates into the aixPES modular measurement platform. This allows combined studies including polarization and PP-EE loop acquisition, poling procedures, fatigue analysis, and dielectric breakdown tests. Sample holders are available for ceramics, soft materials, and thin films, with modular high-voltage amplifier options. The aixPES platform supports a variety of accessories and control units, including:

- Different high-voltage amplifiers for driving samples with voltages up to several kV.

- Temperature controllers for precise environmental conditioning across a wide temperature range.

- Force controllers enabling highly accurate mechanical stimulus.

- Laser control units for inverse d33 coefficient measurement during poling processes.

- Integration of external instruments such as impedance analyzers and stress-strain measurement systems.

All components and external devices are integrated via a unified software interface, ensuring synchronized control and data acquisition for complex ferroelectric and piezoelectric characterization workflows.

-

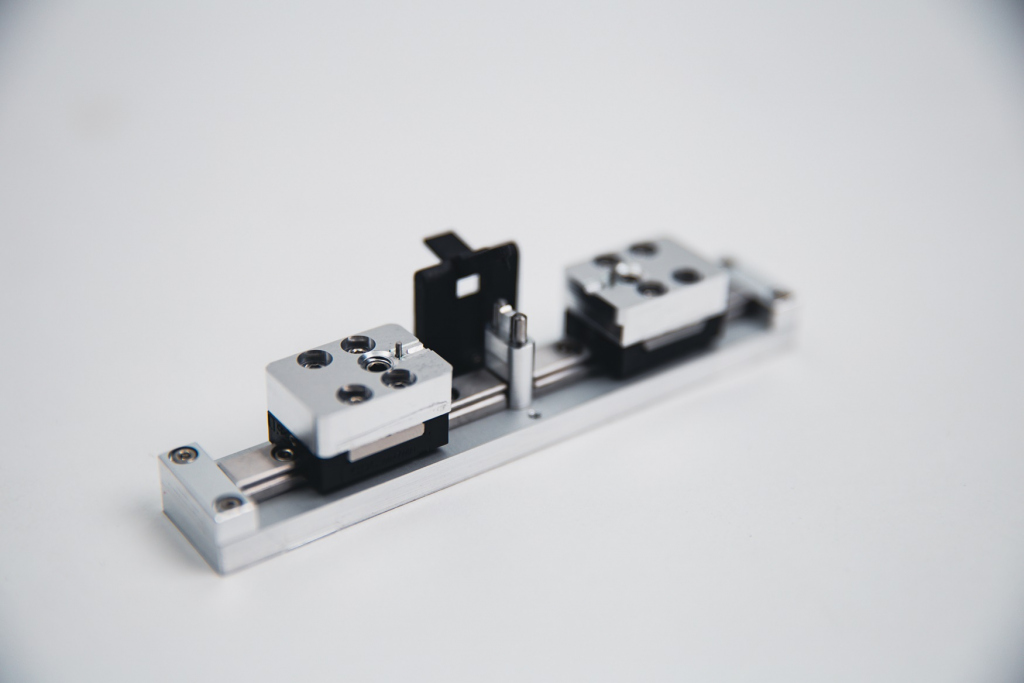

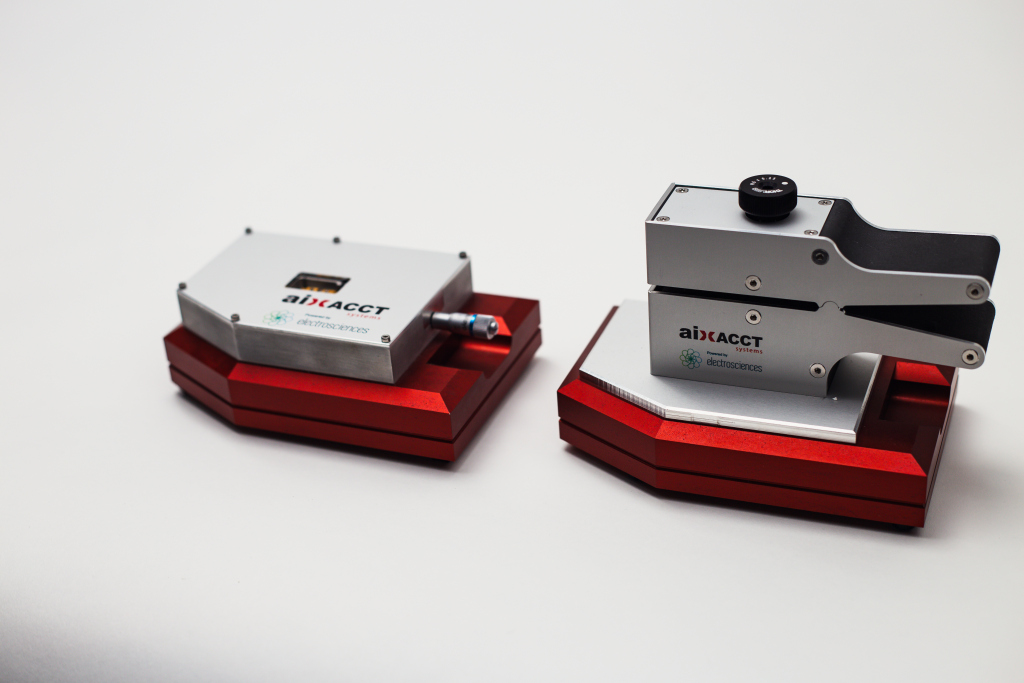

Our base system for measuring d31/d32 coefficients

Measurement Principle

The patented ESPY31 provides SI‑traceable measurement of the in‑plane direct piezoelectric charge coefficients d₃₁ and d₃₂. Measurement uncertainty is quantified through a traceable calibration chain for both force and charge channels.

Calibration and Traceability

The integrated force cell is calibrated against NIST mass standards and the local value of g. Electric charge calibration is performed with a traceable current or voltage source. Both calibrations are carried out in‑house, eliminating the need for potentially unstable piezoelectric reference samples.

Measurement Sensitivity

The system achieves 100 fA current resolution with sub‑picocoulomb charge accuracy. This measurement range allows reliable determination of direct d₃₁ and d₃₂. in materials with weak piezoelectric response.

Sample Loading and Clamping Geometry

Patented clamps and flexure guidance minimize clamping artifacts, suppress off-axis strain, and enforce a strictly tensile geometry. This yields uniform on-axis strain with zero off-axis contribution, by suppressing parasitic contributions from other components of the piezoelectric tensor. Such components can be d₃₃ (out-of-plane compression or bending), shear components d₁₅, d₂₄ (transverse motion or twisting), flexional (bending) artifacts (a non-uniform stress gradient through the sample’s thickness). The clamp design prevents slippage and reduces measurement uncertainty.

Piezoelectric Coefficient Determination

Determination of the direct piezoelectric charge coefficients is based on directly measured quantities—generated charge Q, applied force F, and the defined electrode area. This avoids reliance on bending‑beam curvature interpretations or assumptions concerning strain gradients.

Electrical Property Measurement

The system measures capacitance, dielectric loss, and leakage current, under both zero‑bias and DC‑bias conditions. Measurements may be taken before, during, and after mechanical excitation, enabling assessment of dielectric response, electromechanical fatigue, and electrode degradation during cyclic loading.

Frequency Response Characterization

Frequency‑dependent response is obtained using automated sweeps. This includes resonance mapping in addition to static coefficient determination.

Environmental Testing

When operated in a controlled climate chamber, measurements can be performed as a function of temperature and humidity. This allows investigation of phase transitions, thermal cycling, and environmental ageing mechanisms. Susceptibility to humidity and reactive atmospheres can also be probed. In this way, intrinsic material behavior is linked directly to operational reliability under realistic service conditions.

Sample Requirements

The instrument is designed for free‑standing film specimens. The standard sample dimension is 2 mm×4.5 mm, with electrodes applied to both major surfaces.

Features

Determination of the direct piezoelectric d31 and d32 coefficients User-independent measurement repeatability: standard deviation < 0.03 pC/N Unrivalled measurement precision: 100 fA current resolution and sub-pC charge accuracy Uniform mechanical force application eliminates bending/torsional forces Compatible with a temperature-controlled humidity chamber Sensing of temperature and humidity next to the sample Electrical characterization: polarization, capacitance, dielectric loss, permittivity, leakage current Automatic data acquisition with user-defined scripts Handmade in Germany Determination of the direct piezoelectric d31 and d32 coefficients

User-independent measurement repeatability: standard deviation < 0.03 pC/N

Unrivalled measurement precision: 100 fA current resolution and sub-pC charge accuracy

Uniform mechanical force application eliminates bending/torsional forces

Compatible with a temperature-controlled humidity chamber

Sensing of temperature and humidity next to the sample

Electrical characterization: polarization, capacitance, dielectric loss, permittivity, leakage current

Automatic data acquisition with user-defined scripts

Handmade in Germany

Specifications*

Piezoelectric range 0.05-2000 pC/N Frequency range 0.1 to 500 Hz Static pre-load range 0.1 – 5 N Dynamic load range 0 - 1000 mN Resolution static/dynamic load 0.1 mN Repeatability better than 0.03 pC/N in a PVDF Reproducibility better than 0.1 pC/N in a PVDF Sample configuration Free-standing, double-sided electrodes

Geometry: 4.5 mm x 2 mm

Thickness: 10 μm to 1 mmTemperature and humidity -20°C to 80 °C

10 % to 85 % RHExcitation options Waveform, mechanical preload, ac amplitude, measurement time, pre-conditioning cycles Piezoelectric range

0.05-2000 pC/N

Frequency range

0.1 to 500 Hz

Static pre-load range

0.1 – 5 N

Dynamic load range

0 - 1000 mN

Resolution static/dynamic load

0.1 mN

Repeatability

better than 0.03 pC/N in a PVDF

Reproducibility

better than 0.1 pC/N in a PVDF

Sample configuration

Free-standing, double-sided electrodes

Geometry: 4.5 mm x 2 mm

Thickness: 10 μm to 1 mm

Temperature and humidity

-20°C to 80 °C

10 % to 85 % RH

Excitation options

Waveform, mechanical preload, ac amplitude, measurement time, pre-conditioning cycles

* For more specifications and details, contact us at sales@aixacct.com

-

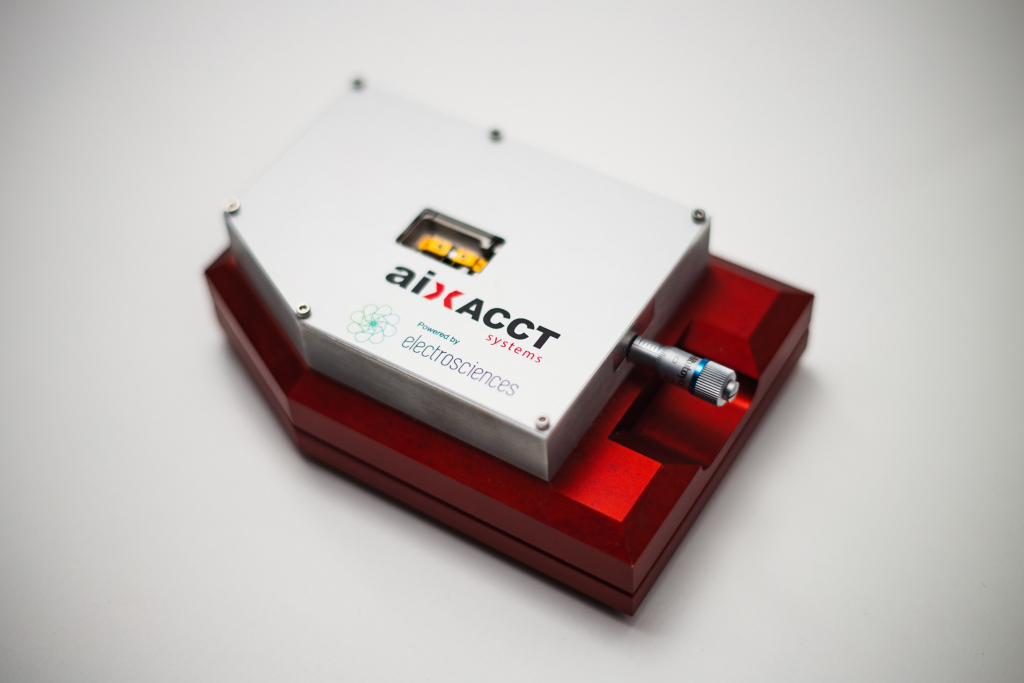

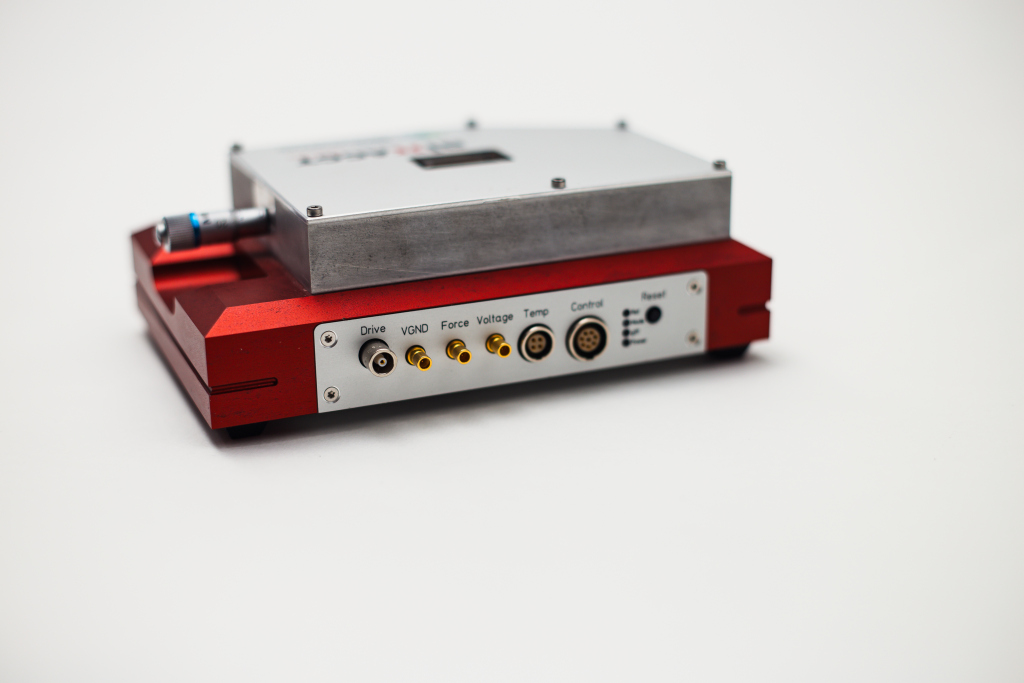

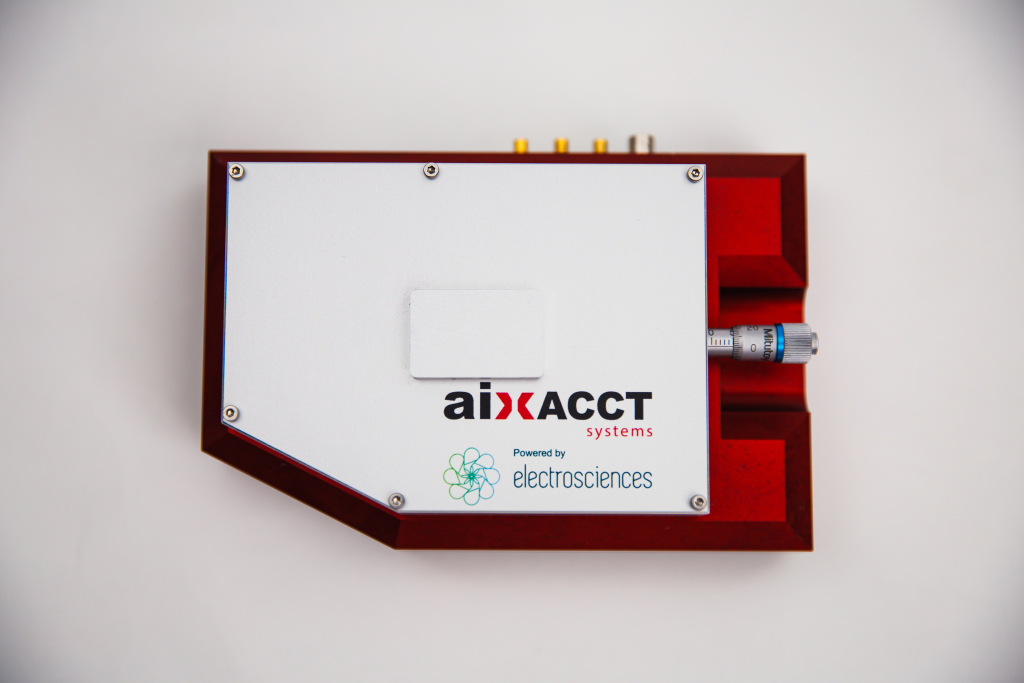

ESPY33 – Precision Measurement of the Piezoelectric d33 Coefficient

Measurement Principle

The ESPY33 implements a refined Berlincourt method for direct determination of the piezoelectric charge coefficient d33. Its core element is a patented integrated force measurement cell, which is mechanically aligned with the sample fixture to apply axial loads without lateral components.

Calibration and Traceability

Conventional measurement devices for direct piezoelectric coefficient assessment often rely on reference piezoelectric materials, which can drift or degrade over time due to stress, temperature, or humidity, compromising accuracy and reliability. In contrast, the ESPY33 is traceably calibrated and does not rely on reference sample measurement.

The applied force is traceably calibrated against NIST mass standards, and the local gravitational acceleration g. Electric charge is calibrated using a traceable current or voltage source. Both channels are calibrated in-house, providing full SI traceability without reliance on reference piezoelectric standards that degrade with stress, temperature, or humidity.

Measurement Sensitivity

The system achieves 100 fA current resolution with sub‑picocoulomb charge accuracy. This sensitivity supports characterization of materials with weak piezoelectric response, where generated signals are close to typical noise levels.

Sample Loading and Electrode Geometry

Compliant piezoelectric materials tend to be susceptible to deformation, which can lead to inaccurate measurements of the piezoelectric coefficients of these materials. Electrode geometry has been optimized for uniform electric field distribution and homogeneous mechanical stress. Preload force (static force) can be adjusted by the user, minimizing depoling effects and improving measurement repeatability for compliant materials.

Coefficient Determination Principle

Determination of d33 is derived directly from measured charge Q, applied force F, and known electrode area.

Electrical Property Measurement

In parallel with piezoelectric measurements, the instrument can record capacitance, dielectric loss (tan δ), and leakage current. Data acquisition may be performed before, during, or after mechanical excitation, with optional DC bias applied. This supports analysis of dielectric behavior, electromechanical fatigue, and electrode stability under combined electrical and mechanical stress.

Frequency Response Characterization

Frequency‑swept operation enables assessment of both mechanical and electrical resonances, extending characterization beyond quasi‑static coefficient values.

Environmental Testing

ESPY33 can be operated within a temperature–humidity chamber. This enables studies of temperature‑dependent coefficients, ferroelectric phase transitions, thermal cycling behaviour, ageing, and humidity or atmosphere induced degradation. Correlation of intrinsic d33 response with environmental conditions enables assessment of long-term reliability under realistic service environments.

Sample Requirements

Electroded samples provide well‑defined measurement volume and are recommended. Non‑electroded specimens may also be measured; in this case the effective interaction volume is determined by electrode–sample contact area.

Keyfeatures

The ESPY33 is ideal for manufacturers, researchers, and institutions requiring accurate evaluation of piezoelectric materials’ functional properties. Applications span various industries, including medical imaging, energy harvesting, and flexible actuators.

Specifications*

Piezoelectric Range 0.1 to 2000 pC/N Frequency Range 10 mHz to 500 Hz Static Preload Range 0.1 to 10 N Dynamic Load Range 0 to 1000 mN Load Resolution 0.1 mN Sample Geometries films, coating, plates, discs, rods, crystals Sample Size typically 5 mm to 25 mm diameter Environmental Conditions -20°C to 80°C, 10% to 85% RH Excitation Options Waveform, static preload, dynamic load, measurement time, pre-conditioning cycles Electrosciences can provide traceable reference samples, if required for Quality Assurance or other Quality Management System purpose. Piezoelectric Range

0.1 to 2000 pC/N

Frequency Range

10 mHz to 500 Hz

Static Preload Range

0.1 to 10 N

Dynamic Load Range

0 to 1000 mN

Load Resolution

0.1 mN

Sample Geometries

films, coating, plates, discs, rods, crystals

Sample Size

typically 5 mm to 25 mm diameter

Environmental Conditions

-20°C to 80°C, 10% to 85% RH

Excitation Options

Waveform, static preload, dynamic load, measurement time, pre-conditioning cycles

Electrosciences can provide traceable reference samples, if required for Quality Assurance or other Quality Management System purpose.

* For more specifications and details, contact us at sales@aixacct.com

Handcrafted in Germany and designed by Electrosciences Ltd (UK), the ESPY33 ensures high precision, excellent measurement repeatability, and long-lasting performance.