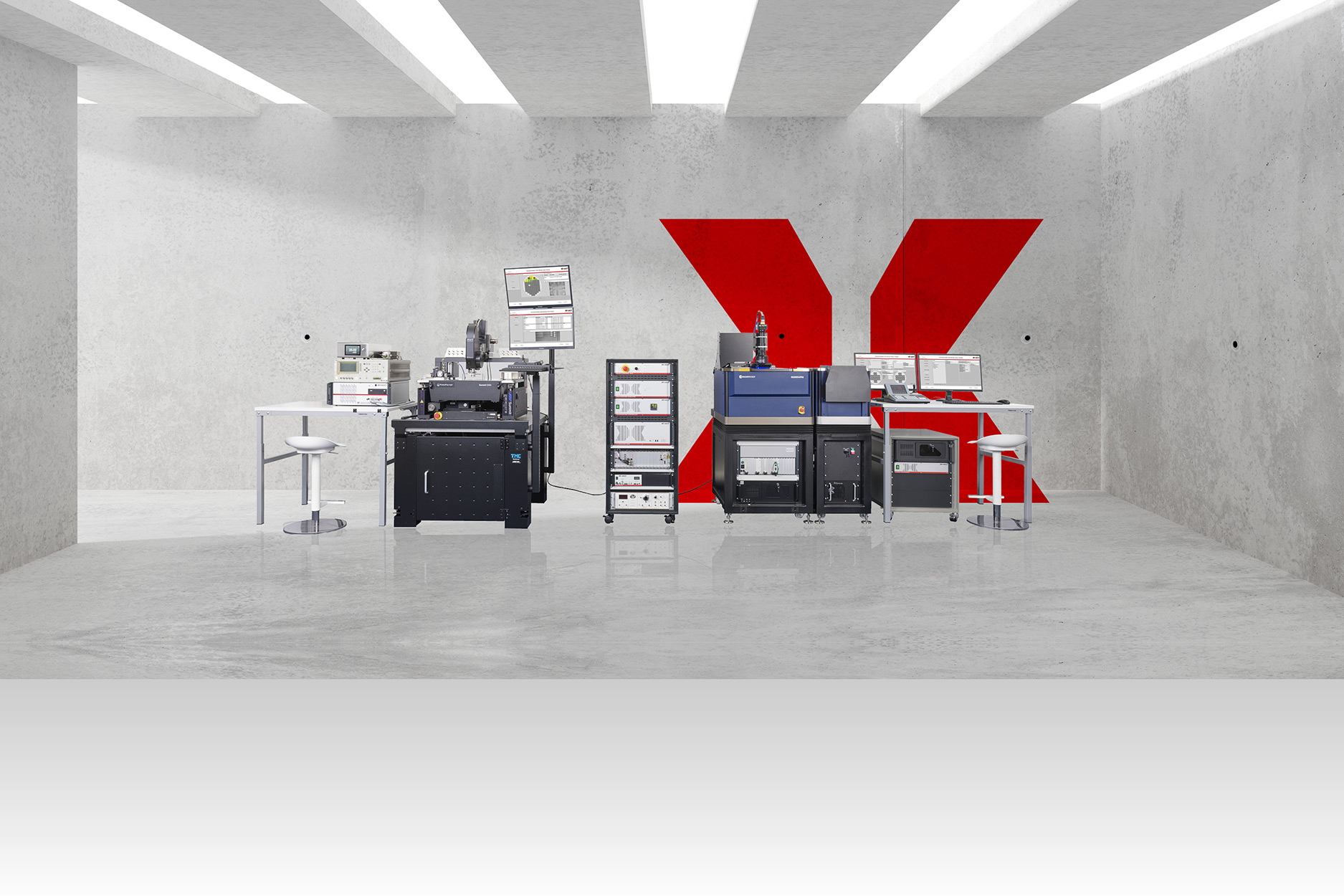

Production tools based on wafer probers

Our range of production tools includes systems based on wafer probers. During the production process, they can be used to determine electrical, electromechanical, thermal and pyroelectric properties at certain points, for example. The first measurement system to integrate a wafer prober was our double-beam laser interferometer (DBLI). This system determines the d33,f coefficient. Depending on the prober fittings, it can also automatically load and align the wafers.

Intuitive operation

All of our systems, DBLI, PIAS and CIT, are controlled by intuitive software. Regardless of which prober or measurement system you use, the basic control structure is always the same. Different access rights for users ensure that your staff can operate the complex system without the need for in-depth training in advance.

You can of course connect the system to higher-level control units, such as via a SECS/GEM interface.

We focus not only on the software developed specifically for prober-based systems, but also on the integration of hardware components. From our globally unique double-beam laser technology and the incorporation of highly specialized camera units, or a laser system for point heating on structures, anything is possible. Simply get in touch!